Alfa Laval Contherm Scraped Surface Heat Exchangers

Contherm scraped-surface heat exchangers are designed for heating and cooling operations in the continuous and semi-continuous processing of many food, health, and beauty aid products. Contherm units are specially designed for applications where products are sticky, viscous, or have high solids content that are more difficult, if not impossible, to heat with other standard methods of heat transfer.

The wide variety of sizes and configurations allow Alfa Laval to meet the requirements of almost any application.

Models

- Contherm

- Contherm Core

- Contherm Select

- Contherm Max

- Contherm Evaporator

- Contherm Max Evaporator

Application

The Contherm™ scraped-surface heat exchanger (SSHE) has found use within many different processes and applications for manufacturing food, chemicals, pharmaceuticals, cosmetics, health, and beauty products. It is particularly suited for processing viscous, heat sensitive, sticky, or chunky (containing particulates) products that are to be pumped. It can be used in a broad range of processing environments, including: aseptic, heating, slush-freezing, sterilization, cooling, pasteurization, crystallization, and phase change.

Design

The Contherm is designed to comply with the most stringent industry standards. USDA and 3-A hygienic design documentation is available for special executions. The Contherm is manufactured according to ASME and PED. Other pressure vessel codes are available on request. The Contherm SSHE can operate with a large flexible range of media types, such as steam, thermal oil, water, glycol, brine, Freon™, ammonia, and other liquefied gas refrigerants.

The standard execution is vertically mounted on a column. The column needs to be secured to either a wall or the ceiling. The rotor is placed on ball bearings and is driven by an electrical motor, which is installed on the upper end of the unit. Mechanical seals at each end of Contherm prevent product leakage and external contamination. Rotating scraping blades are secured to pins welded to the rotor. A hydraulic lifting device provides an easy way to lower the rotor and blades for maintenance and inspection. Tangential inlet/outlet ports provide gentler handling of the product, resulting in better product integrity and quality by allowing product to enter and exit cylinder in same direction as the turning rotor.

Specifications

| Working Temperature | Product side | -30°F to +338°F |

| Media side | -30°F to +338°F | |

| Maximum Working Pressure | Product side | 300 psig and full vacuum |

| Media side | 250 psig | |

| Connection | Product side | 2.0 inch DIN, Tri-Clamp®, SMS, other 3.0 inch DIN, Tri-Clamp®, SMS, other |

| Media side | 2.0 inch upper - NPT or flange 1.5 inch upper - NPT or flange |

Working Principle

Product enters the cylinder through the lower product head and flows upwards through the cylinder. At the same time, the heating/cooling media travels in counter-current flow through the narrow annular channel between the heat transfer wall and the insulated jacket. Rotating blades continuously remove product from the cylinder wall in order to ensure uniform transfer of heat between media and product. An optional coil in the annulus increases media velocity, adding to the heat transfer efficiency. Product exits the cylinder through the upper tangential port. On start-up, air is completely purged from the Contherm. At the end of a processing run, the product can be drained or “chased out” by water resulting in minimal product loss.

Scraper configuration, rotor diameter, and rotor speed can be varied to suit the properties of the particular product flowing through the cylinder. Numerous Contherm configurations are available. Call CSI to discuss customizing a Contherm unit by selecting the appropriate materials, features and options to meet your exact requirements.

Flow Rate

The Contherm’s maximum flow rate is application specific and determined by the temperature program, nature of the product, and type of duty.

MATERIALS

The heating surface is made in 316L stainless steel, honed to a very high finish on the inner surface. The scraping blades are made of Alfalon® III, Nylon, and Teflon material. Seal options are single carbon mechanical, carbon flushed / aseptic, hard face, and hard face flushed / aseptic. Suitable materials will be selected for special applications.

OPTIONAL FEATURES

The following optional design features are available: Alternative mounting configurations, including a horizontal option for use in facilities with limited ceiling height. Control panel with automatic maintenance status feature to prevent product freezing if flow is interrupted. Refrigeration (accumulator) or heating/cooling valve packages. Rotors in different sizes: 3 inch diameter, 4 inch diameter, 14.5 inch diameter, or 5 inch diameter. 27 barg product-side pressure rating is available.

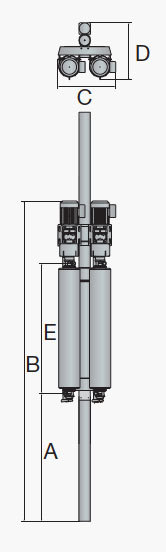

Dimensional Data

| Model | Heating Surface (ft2) | A (in) | B* (in) | C (in) | D (in) | E (in) | Net Weight (lb) | Floor Space (ft2) |

|---|---|---|---|---|---|---|---|---|

| 6x3 | 3.0 | 33.6 | 98.5 | 34.0 | 36.8 | 28.2 | 308 | 3.6 |

| 6x6 | 6.0 | 54.6 | 143.5 | 34.0 | 36.8 | 52.2 | 515 | 3.6 |

| 6x9 | 9.0 | 78.6 | 191.5 | 34.0 | 36.8 | 76.2 | 605 | 3.6 |

| 6x11 | 10.5 | 92.7 | 224.0 | 34.0 | 36.8 | 86.8 | 675 | 3.6 |

*The height may vary depending on the size of the motor

Product Resources

See all resources by Alfa LavalLiterature

Create a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

Create a MyCSI Dashboard to save resources for quick reference, track orders, and talk with experts.

It only takes a minute.

Sign in

Sign in to save resource to your dashboard.

Literature for Contherm Scraped Surface Heat Exchangers have been saved to your dashboard!

Literature for Contherm Scraped Surface Heat Exchangers are already in your dashboard.