The Benefits of Heat Exchangers In Process and Clean-in-place

Food, beverages, and pharmaceutical processing systems require the addition and removal of heat in order to function properly, and processes must be carefully controlled to maintain proper temperatures. Heat exchangers regulate fluid temperatures in processing systems to meet requirements for pasteurization, filling operations, and food safety.

In the food and beverage industry, heat exchangers reduce or eliminate microbials to make products safe for consumption and to prevent spoilage.

Heat exchangers also heat or cool products during a variety of processing stages, including filling, drying, and concentration. To meet processing requirements for a variety of products and their varying viscosities, heat exchangers use innovative designs to maximize efficiency.

For example, plate heat exchanger technology is vital to dairy, beverage and processed food applications. They provide the exact combination of temperature and holding time, for precise pasteurization and ultra-high temperature treatment and regeneration in a variety of applications:

- Milk and cheese milk pasteurization

- Ultra-high temperature sterilization

- Beverage and energy drink pasteurization

- Standard and pulpy juice pasteurization

- Beer wort heating and beer cooling

- Liquid egg processing

- Bottled water treatment

- Soups, sauces and starch heating

- Ketchup and mustard heating and cooling

Pharmaceutical, food, and beverage operations realize the value of heat exchangers in several ways:

- Heat exchangers heat the cleaning fluids that remove residues from systems components.

- Heat exchangers create consistent temperatures for pasteurizing and Clean-in-place (CIP).

- They heat water for effective rinsing of food production equipment (tanks and piping).

- They can be placed on skids for small-footprint, flexible CIP equipment positioning.

- Heat exchangers themselves are CIP'able because their designs induce turbulence when systems maintain sufficient flow rate.

- They transfer heat without contaminating the heated fluids.

- Energy savings: regenerative heat transfer conserves energy by re-using heated fluids to heat fluids in repeatable cycles.

Save Energy With Heat exchangers

Pasteurization relies on a heat exchanger’s ability to recover heat from processed milk. For pasteurization, milk has to be stored at 4°C to prevent microbial growth. During pasteurization, milk is heated to a temperature of 72 °C for at least 15 seconds to kill pathogens, and then chilled back to 4 °C to stop the process and preserve the milk.

The heat of the pasteurized milk is used to warm the cold milk. The incoming cold milk is preheated by the outgoing hot milk, which is simultaneously pre-cooled. This transfer efficiency saves heating and refrigeration energy.

The process is called regenerative heat exchange or heat recovery. As much as 94 – 95% of the heat content of the pasteurized milk can be recycled.

The Handbook of Water and Energy Management In Food Processing reports that potential energy savings of between 50 and 70% could be achieved with heat recovery, depending on viscosity and design of exchanger. Greater efficiencies in processing also result in lower water consumption worth thousands of dollars per site (P. 564).

Heat exchangers also have an important role in clean-in-place, which is the process of cleaning system components without having to dismantle or open the equipment for cleaning. In CIP, the main purpose of heat exchangers is to heat the cleaning water and solutions to a consistent temperature to aid in the removal of residue.

While performing their functions in processing and CIP, heat exchangers help reduce utility consumption by conserving water, electricity, and steam. Common applications for heat exchangers include processing for biotech and pharmaceutical, chemical, food and beverage, and personal care products.

Advantages of Each Type of Heat Exchanger

To meet the heating and cooling needs of such an array of applications and products, heat-exchanger designs have evolved to meet a range of site-specific temperature-modulation requirements.

Plate-and-Frame Heat Exchangers

Highly efficient and typically have a small footprint allowing a more compact system design. Additionally, they have a relatively low steam temperature requirement, making them a desirable choice for CIP systems.

Shell-and-Tube Heat Exchangers

Simple, low-maintenance in-line heating option. While these units are widely used for viscous products with particulates in food, dairy, and beverage markets, they are typically found in pharmaceutical applications where complete drainability is required.

Scraped-Surface Heat Exchangers

Used in processing are more costly than other options, but they are the right choice for products that are viscous or sticky or include large particulates.

Flexible plate and frame heat exchangers

Because plate and frame heat exchangers are designed to increase or decrease in capacity depending on application, they are among the most versatile heat exchangers available.

In addition to variations in height and width that accommodate installation and system integration, plate and frame heat exchangers can scale in depth as system capacities change.

Efficient heat transfer of shell and tube heat exchangers

Processors use shell-and-tube heat exchangers for general product heating and cooling. The high shear force and turbulence of their design minimize the risk of biofilm build-up and ensure efficient heat transfer. One manufacturer’s Pharma-line of shell and tube heat exchanger operates at pressures of up to 10 bar and operating temperatures of 150°C, which makes the heat exchanger easy to drain.

Shell and tube heat exchangers meet the industry’s rigorous demands for product hygiene by eliminating the risk of cross-contamination.

Double-duty scraped-surface heat exchangers

By performing heating duties while also scraping interior surfaces to prevent fouling, scraped-surface heat exchangers add value to systems by keeping them running longer between cleaning. In scraped-surface heat exchanger applications, the product enters the cylinder at the bottom and flows upwards.

The heating or cooling medium travels in a counter-current flow through a narrow annular channel. Typical applications include processing of ketchup, mayonnaise, hummus, chocolate spreads, fruit pie fillings, gravies and sauces, whipped/aerated products, peanut butter, pizza sauces, puddings, salad dressings, and baby food, among others.

Rotating blades continuously remove product from the cylinder wall to ensure uniform heat transfer. The product enters the cylinder in a corkscrew pattern in the same direction as the rotating scraping assembly. The design of scraped surface heat exchangers preserves product quality by providing gentler product handling. Both product flow and rotor speed can be adjusted to suit the properties of the product in the cylinder.

Scraped surface heat exchangers are common in the food and personal care industries. Ensuring continuous production requires uniform heat transfer, but the consistency or content of some food products hinders efficient heat transfer. Scraped-surface heat exchangers meet the need for efficiency by keeping product off the walls and in the mix where they belong.

| Plate and Frame | Shell and Tube | Scraped Surface |

|---|---|---|

| High efficiency | Heat transfer to viscous fluids | Heats and scrapes |

| Highly expandable | Higher PSI | Low downtime |

Heating cleaning fluids that remove residues from systems components

Heat exchangers play an important role in maintaining correct cleaning fluid temperatures for clean-in-place.

In all sanitary applications including pharmaceuticals and food processing, cleaning and sanitation must occur at sufficient intervals to prevent equipment fouling, reactions, and cross contamination, and temperature regulation is a key factor in maintaining temperatures during each interval.

Heat exchangers control temperature in CIP fluid supply to circuit-specific set points.

CIP systems connect directly to heat exchanger connections and circulate a mixture of heated non-toxic cleaning agents that effectively remove scale, product deposits, and bio-fouling to clean process surfaces and restore performance of system components. Custom fabricated CIP systems are suitable for very large heat exchangers, which require expertly engineered CIP solutions.

Processing at high temperatures, with hard water, or high pH levels increases risks of fouling or scaling, so cleaning is required to maintain efficiency. CIP equipment circulates cleaning chemicals and rinses to flush interior surfaces of heat exchangers without having to disassemble them.

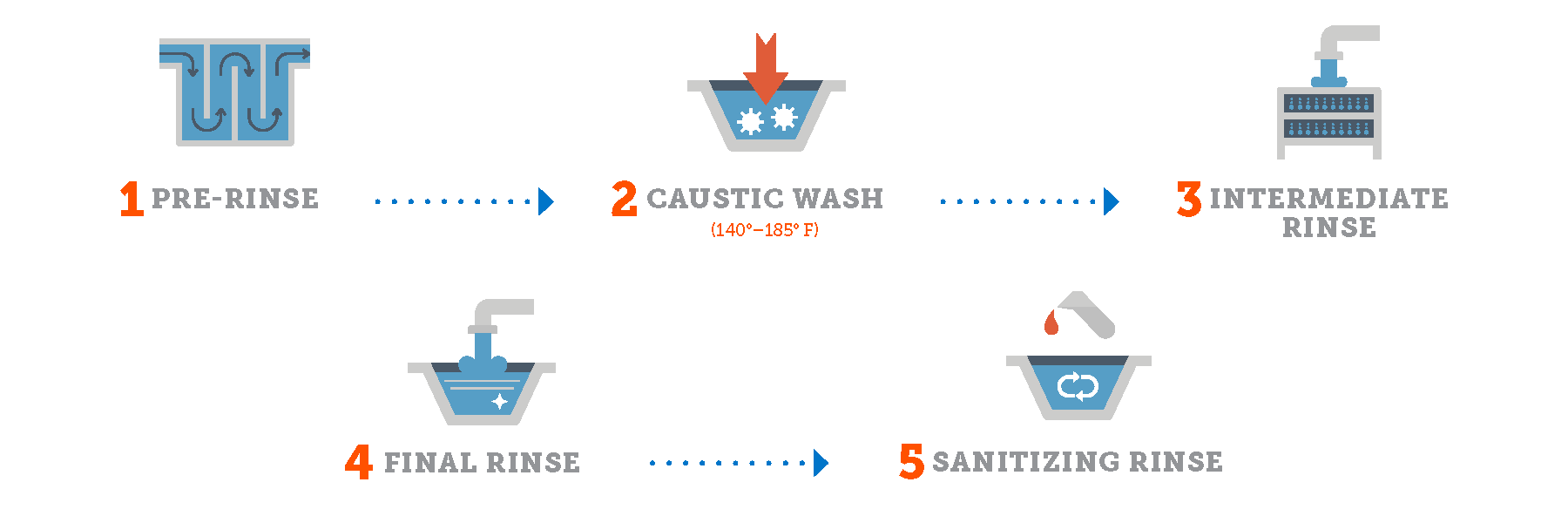

After each cleaning phase, the cleaning solution is routed to a drain or back to the detergent tank for re-use. A normal sequence could include initial water rinse, lye cleaning, intermediate water rinse, acid cleaning and final water rinse followed by chemical or hot water disinfection. The temperature, flow and detergent concentration in the CIP return line are automatically controlled throughout the cleaning cycle.

Heat exchangers are CIP'able

CIP effectiveness is determined by cleaning time, strength of cleaning chemicals, the temperature of cleaning chemicals, and the amount of turbulence, so heat exchangers have a key role to play in operational productivity and effectiveness.

During CIP, the cleaning solution is pumped through the heat exchanger, where it is heated to the required temperature and where plate designs that facilitate heat transfer also create turbulence that aids in plate cleaning. The solution is then routed to the target system and back to the circulation tank included in the CIP module.

Placing heat exchangers on skid for small-footprint, flexible CIP equipment positioning

A CIP skid is a custom-built integrated CIP system mounted on a platform for ease of transportation and installation.

Prefabricated skids make efficient use of space for tanks and piping and they ensure easy access by technicians for connecting to processing systems and other components.

Skids vary by tank size, the number of tanks, heating type, valve type, and chemical dosing. They can include plate and frame, shell and tube, or electric heat exchangers.

Guide to Choosing the Right Heat Exchanger

This guide is designed for processors, production managers, and mechanical engineers to help in the heat exchanger selection process.

Next Steps

As you've learned, to meet processing requirements for a variety of products and their varying viscosities, the correct heat exchanger must be used. This can make the proper selection for your process appear daunting.

We're here to help!

Whether you need parts to keep your current units operating, a direct replacement for a worn out or inefficient heat exchanger, or a new unit for a new process, CSI can support you. Our customer service team, engineers, designers, and product specialists provide solutions through a broad range of brands, technologies, and capabilities.

To learn how we can help, contact us today!

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.