What Are the Different Types of Heat Exchangers?

Most heat exchangers in hygienic processing transfer heat indirectly from warmer fluids to cooler fluids without the fluids mixing together. Heat exchanger types vary to meet requirements for processing efficiency, cost of ownership, and maintenance. In this blog, we describe plate and frame, shell and tube, and scraped surface heat exchangers used in food, beverage, dairy, and pharmaceutical processing.

With supply change challenges among the latest high-priority concerns for contractors and system operators, our Guide to Choosing the Right Heat Exchanger is an invaluable tool for processors, production managers, and mechanical engineers. In this article, we introduce the types of heat exchangers used in food, dairy, beverage, and pharmaceutical processing.

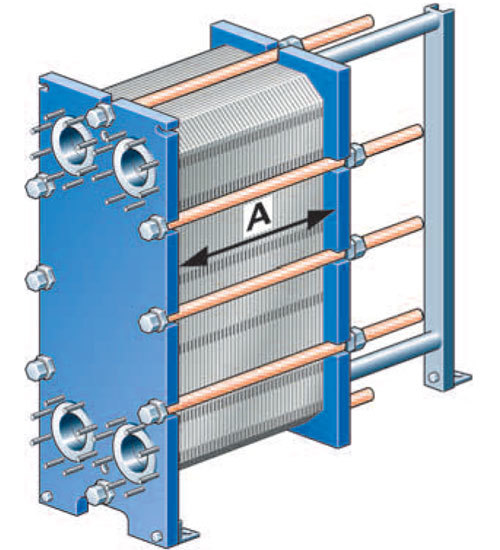

Plate and frame heat exchanger

Plate and frame designs feature corrugated parallel plates separated from each other by gaskets that control the alternating flow of hot and cold fluids over the plate surfaces.

A frame plate and a pressure plate compress gasketed plates together with tightening bolts. Gasketed plates and the pressure plate suspend between an upper bar and a lower guiding bar. The simple mechanical design enables easy cleaning and capacity changes by adding or removing plates.

Hot or cold media flows in alternating channels with processed fluids, and heat transfers from the warmer channel to the cooler channel.

Because of the relatively narrow path between plates and the corrugated design of plates, which create turbulence, plate and frame designs are well-suited to heating fluids of low to medium viscosity.

When fluids are moderately viscous (thick) or include small amounts of particulates, wider gaps between plates can help maintain flow requirements. Wide gaps between plates allow particulates to pass between plates without obstructing flow.

Standard plates typically feature a chevron pattern to maximize plate strength at high pressures. Plates may have different chevron angles to optimize heat transfer for specific pressure drops.

Wider-stream plates have fewer contact points, so they help prevent blockages. They are especially effective for raw juice applications with heating by liquid or steam.

When used for fibrous liquids, viscous, or fluids with particulates, two features of wide-gap plates may ease the flow of fluids or particles:

- Wider gaps between plates than standard designs

- Plate pattern

Double-walled plates consist of two sheets formed together to prevent media from mixing in the event a crack forms in one of the plates.

Gaskets between plates seal the channels to keep fluids separate, to guide flow, and to prevent leaks. Gaskets fit into specially designed plate grooves

Gaskets can be clipped or glued to plates. Clips secure gaskets to the plate to prevent gaskets from moving and to prevent misalignments and leaking. Clip-on gaskets reduce the time required for re-gasketing.

Regasketing of clip-on gaskets is a process of taking off the old one and clipping on a new one.

For glued gaskets, the process is to remove the old one, clean the sealing surface, glue and heat-treating to set glue.

Plates hang from a carrying bar and a guide bar keeps plates vertically aligned. Operators compress the plates between the end plate and pressure with tightening bolts and nuts.

Typical applications for plate-and-frame heat exchangers include:

- Low to medium viscosity products with little to no particulate: milk, cream, ice cream mixes, beverages, beer, beer wort.

Channels are all consistent size

One extra wide channel for fibrous/dirty fluid (A) and one channel for non-fibrous fluids (B)

Two wide channels for fibrous/dirty fluids (C)

Shell and tube heat exchanger

Shell and tube heat exchangers transfer heat between fluids that pass through a bundle of tubes and fluids within a large shell vessel that surrounds the tubes. Tubes inside the shell can enable processing of fluids that are more viscous or contain more particulate than a plate and frame heat exchanger.

Because applications differ widely, shell and tube designs have evolved to meet specific processing requirements.

Monotube heat exchangers — also called tube-in-tube, and jacketed tube — consist of an external shell and a single inner tube. Monotube designs are used in heat-treating applications for products that many times include large particles or have high-pulp or high-fiber ingredients.

Annular models of tube heat exchangers apply heat to product from the inside and outside simultaneously to prevent layering. Annular space designs typically have three to four concentric tubes.

Multitube types have a bundle of inner tubes. They are designed for processing heating, cooling, and heat recovery of low viscosity products that include pulp, fibers, and particulates.

Single tubesheet design: Tubesheets hold tubes in place at one end of the shell. When tubes are placed inside a shell, tubesheets cap one end of the shell to contain heating or cooling fluids. In addition to the tubesheet, baffles hold tubes in place within the body of the shell.

Double tubesheet design: For applications where detecting leaks or mixing of the tube-side fluid with the shell-side fluid is especially warranted, double tubesheet designs afford easy spotting of both.

The risk of mixing between product and heating/cooling fluid is greatly reduced because as product flows through the tubes, the heating/cooling fluid is sealed in the shell by the first tube sheet, and the second tube sheet seals the product.

The gap between the two tubesheets is open to view for easy leak detection. While typically a feature of pharmaceutical processing, double-tubesheet designs can be used in any application utilizing a shell and tube heat exchanger.

Typical applications for shell-and-tube heat exchangers include:

- Low to medium viscosity products: depending on specific product selected can contain varying size of particulate. Beverages with pulp, purees, WFI, lotions, gels, high fouling dairy products.

Scraped surface heat exchanger

Some applications require heat transfer to highly viscous and/or sticky products. In those applications, scraped surface heat exchangers are the best method to provide effective heat transfer due to the scraping blades that keep product from settling on the interior surfaces.

Product enters a cylinder at the bottom of the scraped surface tube. Heating or cooling fluids travel in a counter-current flow in a cylinder surrounding the product channel.

Blades inside the product channel remove product from the channel wall to ensure uniform heat transfer to the product.

The scraping blades are made a variety of materials to meet different processing requirements, and are designed specifically for gentle product handling to avoid compromising product quality and consistency.

Scraped surface exchangers can be mounted vertically or horizontally. Inside, an electric motor turns a rotor fitted with scraping blades.

To prevent damage to product, rotors turn and product the move through the heat exchanger in the same direction, with product entering at the bottom and exiting at the top.

The heating surface is polished to a high finish on the inner surface.

The seals are made of single carbon mechanical, carbon flushed / aseptic, hard face and hard face flushed / aseptic. Suitable materials will be selected for special applications.

Typical applications for scraped surface heat exchangers include:

- Viscous products: Ketchup, mayonnaise, hummus, peanut butter, puddings, salad dressings, bread dough, gelatine, baby food, skin lotions, and shampoos.

- Heat-sensitive products: Egg products, fruit purées, cream cheeses, and fishmeal.

- Crystallizing and phase changing products: Coffee/tea extracts, icings and frostings, sugar concentrates, margarines, shortening, spreads, gelatine broth, lard, fondant, and, beer and wine.

- Particulate products: Meats, poultry, pet foods, jams and preserves, and rice puddings.

- Sticky products: Caramel, cheese sauces, processed cheese, gums, gelatine, mascara, and toothpaste.

Guide to Choosing the Right Heat Exchanger

This guide is designed for processors, production managers, and mechanical engineers to help in the heat exchanger selection process.

Next Steps

As you've learned, heat exchanger styles can vary widely based on a number of variables, which can make the proper selection for your process appear daunting. We're here to help!

Whether you need parts to keep your current units operating, a direct replacement for a worn out or inefficient heat exchanger, or a new unit for a new process, CSI can support you.

To learn how we can help, contact us today!

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.