Top 7 Reasons to Purchase a Plate-and-Frame Instead of a Shell-and-Tube Heat Exchanger

As the two most common heat exchangers, plate-and-frame and shell-and-tube designs, both have a lot to offer when you want to heat or cool a product during processing. Heat exchangers work by transferring heat from one media to another via tubes or plates.

In some applications, however, plate heat exchangers (PHE) have several advantages over shell-and-tube designs. In this post, we discuss application requirements that make PHE the right choice.

What is a plate-and-frame heat exchanger?

Plate heat exchangers have several essential functions in food, dairy, beverage, and pharmaceutical processing:

- Changing and maintaining consistent temperatures for pasteurization

- Transferring heat without contaminating heated fluids

- Achieving energy conservation by re-using heated fluids to heat fluids in repeatable cycles

- Heating water and cleaning fluids for use in efficient cleaning-in-place (CIP)

- Enabling precise control of temperature during sanitizing phases

In the following sections, we will show you how a plate heat exchange is the P.E.R.F.E.C.T. choice for your next heat-transfer solution.

1. Pressure Drops Are Lower

Due to the lower area required with a PHE, PHE designs typically have an overall pressure drop substantially lower than a tubular designed for the same specifications. This lower pressure drop adds to the overall energy efficiency of a PHE over a tubular heat exchanger.

Plate heat exchangers are up to five times more efficient than shell-and-tube designs. In many cases, you can utilize more heat by replacing existing shell-and-tube models with compact plate and frame heat exchangers.

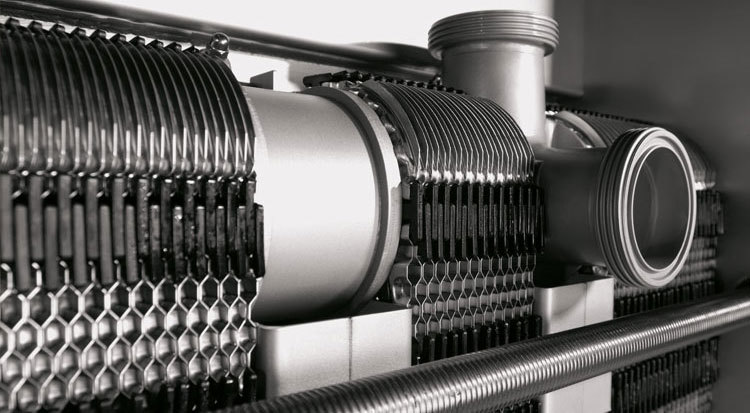

The series of plates in a plate-and-frame heat exchanger creates gasketed spaces between plates. These spaces alternate between two fluids—one hot and one cold.

The design delivers very high heat transfer efficiency because the plates create a surface area that’s much larger than shell-and-tube designs that would fit in the same space.

2. Efficiency

Typically, a plate heat exchanger is the right choice because they’re the most efficient and least expensive option.

Plate heat exchangers are up to five times more efficient than shell-and-tube designs.

- Higher heat transfer coefficients can be attained due to the corrugated plates and higher velocities

- Closer temperature approaches due to pure counter current flow, allowing for more heat transfer

- Higher amount of regeneration possible due to these closer temperature approaches

The series of gaskets in a plate-and-frame heat exchanger creates spaces and formed flow paths between plates. These spaces alternate between two fluids—one hot and one cold (Fig. 1).

Overall Heat Transfer Coefficient (U Value)

The heat transfer coefficient describes the heat energy transferred by the two designs (PHE vs. Shell and tube, Fig. 2, below). The coefficient is a multiplier in the heat transfer equation, so a higher number means more heat transfer occurs. PHE's achieve their improved heat transfer coefficients while having a much smaller footprint and lower weight than their shell-and-tube counterparts.

Overall Heat Transfer Coefficient - U - | ||

Liquid-to-Liquid Heat Transfer | Heat Transfer Coefficient W/(m2 K) | Btu/(ft2 °F h) |

Shell and Tube | 150-1200 | 25-200 |

Plate and Frame | 1000-4000 | 150-700 |

Key characteristics of processed fluids

Heat transfer inside a heat exchanger results in temperature changes in both fluids, lowering the temperature of the warmer fluid and raising the temperature of the cooler fluid.

Fluid properties partially determine the type of heat exchanger for the application.

Fluid types

- Water

- Oils

- Milk

- Cosmetics

- Pharmaceuticals

Thermal properties of fluids

- Temperature

- pH

- Flow rate

- Corrosiveness

- Viscosity

3. Reduced Maintenance

High-quality plate-and-frame heat exchangers can operate efficiently for ten years without maintenance. Plates are easy to access for inspection or cleaning in place. Cleaning intervals depend on amounts of fouling or scaling.

Plate heat exchangers are much easier to maintain and operate than shell-and-tube because they’re easier to take apart and inspect. You can easily remove plates for service or repair, whereas shell-and-tube models are more labor-intensive and harder to access internally.

Product buildup or scale coating on surfaces reduces the heat exchanger’s thermal efficiency. Because of plate and frame exchangers’ smaller, modular design, they are faster and easier to clean than larger shell-and-tube units.

4. Footprint is Smaller

The surface area in a plate heat exchanger is made compact because of the stacking of the plates. This stacking reduces the footprint of the plate heat exchanger vs a tubular heat exchanger even for units with the same amount of surface area. As Fig. 5 illustrates, making the compact size of a plate heat exchanger also important to applications with tight spaces.

5. Expandability

If a need to expand heat transfer capacity is likely, plate heat exchangers are an excellent choice because you can change capacity easily by adding or removing plates. Planning for future expansion includes sizing of the plate heat exchanger for its initial duty plus space allowance for plate capacity and easy field installation. Shell-and-tube capacities cannot be modified.

Technical note: Adding plates to a PHE decreases pressure drop for identical flow rates as long as the channels (number of plates per direction) are increased and the passes (alternating directions of flow) remain the same, similar to what happens when increasing pipe diameter. In contrast, adding passes increases pressure drop, similar to what happens when increasing pipe length (Fig. 4).

Adding Channels

Adding Passes

6. Capital expense

Cost of ownership is always a critical factor in the decision-making process. A plate heat exchanger is the lowest cost option because it can achieve high heat transfer coefficients — with pure counter current flow — giving the most efficient heat transfer and lowest surface area. Maintenance cost is also reasonably low, especially compared to scraped-surface heat exchangers. The main expense is the replacement of gaskets and, occasionally, of plates.

The close temperature approach, meaning a cold fluid being heated to a temperature that is very close to the temperature of the entering hot fluid, allows more regeneration and heat recovery, making a plate heat exchanger a good option. Smaller temperature variances between product and media also prevent burn-on in products with moderate to high sugar or protein content.

In addition to the capital expense for the equipment, capital costs can include shipping, handling, installation, and maintenance over the unit’s lifetime.

7. Types of Plates

Plate and frame heat exchangers can be adapter for a variety of product viscosities.

- For viscous products, PHE requires proper plate selection.

- For products with particulate, PHE requires a special plate with low contact points and/or wider gap.

In cases when a PHE has difficulty handling viscous products, it’s typically because it was initially designed for use with fluids of very low viscosity but later used with highly viscous product.

PHE can be adapted to more viscous or particulate products with the exchange of standard-gap (3-5mm) chevron plates for wide-stream plates for fine particulate (same gap but fewer contact points than chevron plates), or wide-gap (up to 8mm) plates that can process larger particulates and higher viscosity. Fig 3. illustrates a range of PHE and plate gap choices by product fiber length, pulp density, and viscosity.

Standard Plate Gap

Channels are all consistent size

Single-sided WideGap

One extra wide channel for fibrous/dirty fluid (A) and one channel for non-fibrous fluids (B)

Double-sided WideGap

Two wide channels for fibrous/dirty fluids (C)

Average Gap | Particle Size | Fiber Length | Pulp % | Viscosity CPS | |

Typical Industrial Plate | 2.4-3.95mm | Dia 0.5mm | 1mm | 2 | 2500 |

Typical Sanitary Plate | 3.95mm | Dia 0.5mm | 1mm | 3 | 5000 |

Low Contact Point Plate | Up to 8mm | Dia 0.5mm | 5mm | 7 | 1000 |

Typical Plate heat exchangers handle low- to medium-viscosity fluids:

- Milk and dairy pasteurization

- Ultra-high temperature sterilization

- Beverage and energy drink pasteurization

- Standard and pulpy juice pasteurization

- Beer wort and beer pasteurization and cooling

- Liquid egg processing

- Bottled water treatment

- Soups, sauces, and starch heating

- Ketchup and mustard heating and cooling

Despite the prevalence of shell and tube and tubular heat exchangers, a Plate and Frame heat exchanger will always be the most efficient and cost effective form of heat transfer for products with fine particulate and low to medium viscosity.

~ Melissa Fryer, Sanitary Heat Transfer Business Development Manager, Alfa Laval

Summary: Advantages and Disadvantages of Plate and Frame Heat Exchangers

Advantages

- Relatively inexpensive compared with other designs

- Excellent CIP-ability

- Easy to clean and maintain

- High heat regeneration

- High turbulence

- Replaceable gaskets

- Easy to increase/decrease capacity

- Smaller footprint than shell-and-tube designs

Disadvantages

- Relatively low operating temperature

- Maintenance cost due to gaskets

- Not for use with products of very high viscosity or with very large particulates

Guide to Choosing the Right Heat Exchanger

This guide is designed for processors, production managers, and mechanical engineers to help in the heat exchanger selection process.

Next Steps

As you've seen, plate and frame heat exchangers provide a variety of benefits over shell-and-tube designs. However, even with this knowledge, making the proper selection for your process appear can still appear daunting. We're here to help!

Whether you need parts to keep your current units operating, a direct replacement for a worn out or inefficient heat exchanger, or a new unit for a new process, CSI can support you.

To learn how we can help, contact us today!

Contributing Author

Melissa Fryer is the Sanitary Heat Transfer Business Development Manager for Alfa Laval’s Food Heat Transfer team. Melissa received her B.S. degree in Chemical Engineering from The State University of New York at Buffalo, and brings over 25 years’ experience in specifying, calculating and troubleshooting heat exchangers in the food, beverage and dairy market. Melissa focuses on engineering solutions to meet customer needs and possesses extensive knowledge of and passion for this industry.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.