What is a Rotary Lobe Pump?

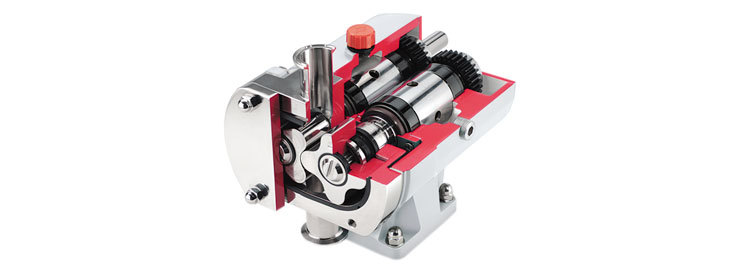

Rotary lobe pumps are positive-displacement type pumps that use two or more lobes rotating around parallel shafts in the pump’s body to move liquids. They are widely used in the hygienic processing industries, including food & beverage processing and biopharmaceutical manufacturing.

In the following paragraphs we will describe lobe pumps in detail:

- What they’re used for

- How they work

- How to get the most out of their performance

Unlike gear pumps, the lobes used in these pumps do not make physical contact with each other, a feature that provides some distinct advantages in pumping certain types of materials.

The shafts to which the lobes are attached rotate in opposite directions when in operation, repeatedly creating and then collapsing cavities inside the body of the pump, and moving product from the pump's inlet port around the outside of the pump’s lobes to the outlet port.

Since the movement of the pump’s lobes cause the pump to discharge a specific amount of fluid each revolution, the pump’s output can easily be controlled by mechanically varying the speed of the pump’s motor, typically with the use of a variable frequency drive (VFD).

Stainless steel lobe pumps manufactured by companies such as Alfa Laval and Ampco are widely used throughout the sanitary processing industries.

Advantages of Rotary Lobe Pumps

- Since the pump’s lobes do not come into contact with each other, lobe pumps can move solids suspended in slurries (such as cherries or olives in food processing applications) without product damage.

- The gentle pump action further minimizes product degradation.

- Can handle larger sized particles than may be pumped with other types of positive displacement pumps.

- May be easily cleaned using either clean-in-place (CIP) or steam-in-place (SIP) methods, making them ideal for hygienic processing applications.

- Highly efficient for pumping very viscous liquids.

- Offer accurate and consistent fluid output that is unaffected by changes in head pressure, assuming sufficient fluid viscosity.

- The fluid flow can be increased or decreased by controlling the drive speed.

- If wetted, rotary lobe pumps are also self-priming, and can run dry for long periods of time (assuming the pump’s seals are lubricated).

- Generally easy to maintain.

Disadvantages of Rotary Lobe Pumps

- The purchase price of a lobe pump is typically higher than that of other positive displacement pumps, when considered for a particular application

- Since they’re driven with a motor and gear reducer (which affects the pump’s speed and output), rotary lobe pumps have a comparatively large footprint, which can be a factor in installation.

- The two sets of mechanical seals used in lobe pumps adds to the cost of maintenance and overall ownership.

- The design of lobe pumps requires the use of pressure release and safety bypass valves, adding to their complexity.

- The efficiency of lobe pumps is compromised when pumping low viscosity fluids.

Getting the most out of your lobe pump’s performance

Rotary lobe pumps deliver a defined volume of fluid for each cycle of operation (i.e., each turn of the lobes). The only factor, aside from slip (mentioned later), that determines the amount of fluid being pumped is the speed at which the lobes turn (i.e., the pump’s operating speed, not the motor’s RPMs). Most lobe pumps use gearboxes to increase or decrease the operating speed.

To calculate the amount of fluid pumped at a given speed, pump engineers turn to what’s called a pump curve. These engineering calculations are commonly used to determine the performance of positive-displacement type pumps with different types of fluids and at different operating parameters.

Two variables are typically plotted on pump curves: the pump’s speed in RPMs and the pump’s output in GPM. In the sample illustration, note that there are several lines plotted. This is to account for what’s known as slip, a phenomenon that occurs in positive displacement pumps at varying operating parameters.

Slip is the amount of fluid that flows back from the discharge side of the pump to the suction side of the pump during normal operation.

In other words, slip is the amount of fluid that is recirculated within the pump’s body when it is running, and not pumped out of the pump’s outlet.

The amount of slip in a rotary lobe pump is determined by two factors, the viscosity of the fluid being pumped and the pump’s differential pressure. To the first point, as fluid viscosity increases the amount of slip decreases, since more viscous fluids cannot slip back past the clearances in a pump’s lobes as readily as can thin fluids.

Then, as the discharge pressure of the pump increases, slip will increase as well because the pump is working harder to move fluid from the suction side of the pump to the discharge side and out.

This is somewhat intuitive, as pressure increases, so will slip. Due to slip, most rotary lobe pump manufacturers will plot multiple lines on a pump curve to show the impact of slip with fluids of various viscosities, and under different pump operating conditions.

In simple terms, pump curves are used to determine the output of a rotary lobe pump. They help to figure out what size pump is needed to achieve a certain output. A common saying in the pump world is “the displacement determines the pump and the pressure determines the motor." The curve is useful in determining the needed power (i.e., the horsepower required), given the viscosity of the fluid being pumped, the slip factor, and the pump’s discharge pressure. Contact CSI for more help in developing a pump curve for your particular application.

Rotary lobe pumps offered by CSI

There are a number of global manufacturers of rotary lobe pumps, and CSI is proud to represent two companies, Alfa Laval and Ampco, which provide premier products for hygienic processing applications. Their rotary lobe pumps are described below:

Alfa Laval rotary lobe pumps

OptiLobe Series

Developed for general applications in the dairy, beverage, food, home, and personal care industries, OptiLobe pumps combine cost-effective simplicity and easy maintenance with Alfa Laval quality and reliability.

Certified by the EHEDG (European Hygienic Engineering and Design Group) and 3-A, OptiLobe pumps are fully CIP cleanable and FDA compliant. Flow rates are up to 339 GPM with pressures up to 116 PSI.

SRU Series

Designed for wide ranging applications in the brewing, dairy, food, pharmaceutical, and chemical industries, SRU pumps can handle low to high viscosity media (including creams, gels, cells, and organic solids in suspension); are suitable for CIP; and conform to 3-A sanitary standards.

Compact in size and highly efficient, SRU rotary lobe pumps are capable of flow rates up to 466 GPM and pressures up to 294 PSI.

SX Series

Certified by EHEDG, SX pumps are ideally suited for applications where cleanability and corrosion resistance are paramount. These pumps are also classified for use in potentially explosive atmospheres under the ATEX Directive 94/9/EC Group II, Categories 2 and 3, with temperature classifications T1 to T4.

SX pumps are capable of flow rates up to 566 GPM and pressures up to 218 PSI.

Ampco rotary lobe pumps

AL Series

These pumps combine ease of maintenance, CIP performance, and reliability with economical pricing, and are suitable for a variety of food, dairy, beverage, and pharmaceutical applications.

The AL pump’s unique front-loading seal design provides easier cleaning and reduced maintenance times. Available in flow rates of up to 230 GPM, and pressures of up to 290 PSI.

A Guide to Choosing the Right Pump for Hygienic Applications

This guide is intended for engineers, production managers, or anyone concerned with proper pump selection for pharmaceutical, biotechnology, and other ultra-clean applications.

Next Steps

For sanitary processing applications in both the food & beverage and biopharmaceutical manufacturing industries, rotary lobe pumps are perhaps the ideal solution for pumping highly viscous products and slurries containing suspended solids without product damage.

However, due to the variety of factors described in this article that may impact on rotary lobe pump performance, developing a specific pump performance curve for a particular application is key to choosing the correct size of pump for the job.

Here, CSI can help. Contact us at (417) 831-1411 to discuss your specific rotary lobe pump requirements. We’re here to assist you with your selection.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.