How to Seal Floor/Ceiling Penetrations

In all processing facilities, employee and product safety are the foremost concerns. And a major component in maintaining a safe processing environment is to control the conditions in and around the processing area.

Unsealed gaps in floors and ceilings become pathways that allow airborne particles, moisture, and pests to escape from one area to another where they can contaminate product and create health hazards for employees.

For example, dust production in biopharmaceutical processing can have significant impacts on environmental compliance, employee health and safety, and cross-contamination of materials.

Sealing applications vary widely, so sealing solutions depend on a number of factors:

- Sealing new piping

- Sealing around existing piping

- Sealing around wire, cable, tubing, or hose

- Fire, pressure, or NEMA rating requirements

- Openings in walls, ceilings, or floors

- Openings in thin sheet metal or plastic

- Seals exposed to cleaning solutions or harsh environments

- Seals located outdoors where they are exposed to sunlight and temperature extremes

- Tube-in-tube floor or wall transitions

Sealing piping penetrations in floors and ceilings is therefore an important part of plant operations. In addition to the same factors that can spread contamination through walls — such as air currents — the constant force of gravity and common requirements for positive room pressurization drives the potential spread of contamination through ceiling and floor penetrations.

The Importance of Sealing Penetrations

Sealing all penetrations in a process setting is an important step in producing a safe product and maintaining a healthy work environment. In this post, we focus on floor barriers and penetrations.

For a complete guide to sealing penetrations, please download our Guide to Wall Penetration in Processing Environments & Other Applications.

Potential sources of microbial contamination through floors/ceilings

The FDA has identified several potential sources of contamination in processing plants. Given the number and variety of potential sources, comprehensive sealing is the most effective strategy for preventing contamination.

Ingredients

- Raw produce

- Fresh-cut produce

Packaging materials

- Containers, films, lids, trays

- Processing aids

- Compressed air

- Untreated or inadequately treated wash water

- Ice

- Reused processing water

Facility environment

- Ceilings, overhead structures, catwalks

- Rubber seals around doors (especially coolers)

- Drains

- Walls

- Standing water

- Wet insulation around pipes and cooling units

- Condensate

- Vacuum cleaner contents

- Hand washing areas (sinks) and restrooms

Food contact surfaces

- Fibrous or porous type conveyor belts

- Filling or packaging equipment

- Equipment cleaning tools

- Slicers, dicers, shredders, blenders,

- Belts, peelers, collators

- Containers, bins, tubs, or baskets

- Hands, gloves, and outerwear

- Ice makers

- Utensils

Nonfood-contact surfaces

- In-floor weighing equipment

- Hollow rollers for conveyors

- Trash cans and other such ancillary items

- Visible bearings within equipment

- Condensate drip pans

- Maintenance tools (wrenches, screw drivers, etc.)

- On/off switches

- Cracked hoses

- Equipment framework

- Wet rusting or hollow framework

- Poorly maintained compressed air filters

- Motor housing

- Forklifts, hand trucks, trolleys, racks (U.S. FDA)

- Vacuum cleaners and floor scrubbers

Considerations for utility penetrations

Penetrations created for a structure’s utilities — heating, ventilation, air conditioning, electrical, and plumbing fixtures — also require sealing to prevent contamination and to preserve the integrity of each space’s fire ratings. Perhaps less evident than when sealing wall penetrations, floor/ceiling penetrations often pass between spaces of widely variable uses and temperatures — and therefore fire ratings. Using flexible boot seals helps to maintain rating integrity by protecting fire-rated sealants and insulation from wear and damage.

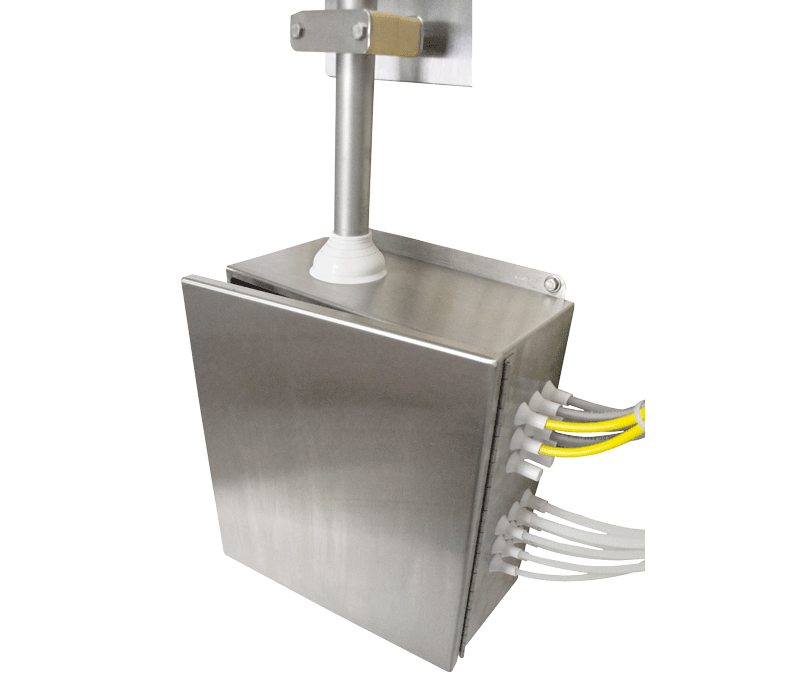

Electrical lines and air-hoses can be sealed, as can plumbing piping, electrical conduit and virtually any other penetrant that must traverse a floor/ceiling barrier.

Sealing of plumbing and sprinkler systems

Plant operators reasonably focus on food processing facilities when thinking about sealing penetrations, but penetrations for plumbing and sprinkler systems are equally important.

Bacteria, dust, and manufacturing residue in pharmaceutical processing — they all act the same way as air and water so always seek paths of least resistance. That’s why all penetrations should be sealed — whether they’re part of the processing system or created by plumbing, heating, or sprinkler systems.

Outdoor Applications

Penetrations that are located outdoors and constantly exposed to the elements are rarely required to be sanitary, but they still need to be properly sealed to withstand exposure to ultraviolet rays and extreme temperature changes. Silicone boots are UV stable and have a temperature range of -40° to 500° F, which makes them less susceptible to degradation.

The aesthetic difference

Floor/ceiling penetrates are more visible than wall penetrations because of high placement (ceilings) or their presence during cleaning (of floors). For that reason, aesthetics often play a role in the design of sealants for floors and ceilings. For example, The Industrial Asset Management Council (IAMC) and the Society of Industrial and Office Realtors (SIOR), name plant design and aesthetics as essential factors in meat processing plants of the future.

Food processing plants of all kinds are more than businesses--they represent social relationships with employees and their communities and therefore have contributions to make to a larger regional identity (Moline, 2015). Silicone boots are by far the neatest, most attractive option available.

Therefore, plants that take pains to keep processing facilities polished without paying attention to penetration seals risk undermining the integrity of their efforts. As the following images show, the choice of penetration seal can make a significant difference in plant aesthetics.

Securing flexible boots to floors and ceilings

Boot rings secure flexible boots to floors and ceilings to stabilize the penetrant and maintain the seal in concrete and metal or to ceiling or floor tiles of various materials.

Auditing Your System to Seal Penetrations

To maintain high sanitary standards, it's essential to routinely audit your system and ensure all penetrations are sealed. By taking the time to review your environment, not only will you increase the aesthetic look and feel, but you'll also guarantee employee safety and product integrity.

What to Review

Open holes and partially sealed holes can create and transfer contaminants.

Flexible boots create seals that prohibit transfer of contaminants.

Neither rubber boots and seals nor metal rings produce any residue so they are more effective than sealing techniques that have the potential of allowing seepage or contributing contaminants of their own. When unsecured caulking dries out and breaks off, it changes from being part of a solution to being part of a problem.

Old or damaged insulation similarly contaminates spaces with dust and particulates.

Avoid utilizing putties, sealants, & caulks on existing pipe

While the pipes below appear to be sealed, water and vibration eventually turn unprotected seals to dust.

Use reboot style of silicone boot to properly seal existing pipe

Boots can be cut to the correct diameter and wrapped around pipes. In addition to adhesive seals, the rings can be secured to ceiling materials with screws.

Gravity works against floor/ceiling sealants by pulling escutcheon plates away from penetrations.

Anchored seals are not susceptible to forces of gravity.

Don't omit sealing plumbing lines in areas that must remain sanitary.

Omitting plumbing lines from a sealing audit can permit contaminants to travel throughout a plant.

Seal all penetrations in sanitary rooms.

Two features of silicone boots for existing piping ensure a tight fit: horizontal cut lines for matching pipe diameters, and metal staples that slide over the seam for crimping.

Flexible sealing boots address the challenges of sealing around existing piping. The pliable silicone boot has a split that allows installers to wrap the boot around the piping. The two reinforced sides of the split seam are made of silicone elastomer that can be crimped together with a stainless steel staple. The result is a permanent, hygienic compression seal that doesn’t crack or separate over time.

Modular mechanical seal assemblies can be installed into existing piping penetrations but should only be used in areas that do not require a hygienic design.

Tube-in-Tube Transitions

Floor penetrations often incorporate a section of pipe or sanitary tube in the opening as a sleeve to protect the process piping running through it. The sleeve often serves as a kick-guard and gives the process piping sufficient room to move and vibrate without restriction.

The gap between the sleeve (outer tube) and the process piping (inner tube) must be sealed to prevent debris from falling into it from above. A tube-in-tube seal for this application must completely seal the gap and allow the inner tube to move and vibrate as needed.

The rigid design of metal escutcheon plates makes them ineffective as tube-in-tube sealing devices.

Fire Rated Applications

Combustible oils, explosive dusts, and flammable liquids and gasses are just a few of the fire hazards in many food and pharmaceutical facilities. Processing environments that contain potential threats to fire safety may require penetrations with some level of passive firestop for delaying or preventing fire from passing through the penetration. Requirements for a proper penetration firestop are addressed in numerous standards and codes:

- Underwriters’ Laboratories UL 1479

- ASTM E814

- NFPA 101 and NFPA 70

- Life Safety Code

- National Electrical Code

- International Building Code

Most of the current standards require more than simply filling an opening with a firestop sealant. They also require a complete system made up of a fire-rated barrier, the penetrating material, and the firestop sealing agent.

Fire codes for your facility are locally developed and enforced, so contact your local fire marshal or building code inspector to learn whether firestop systems are required for your facility.

Several products address firestop applications for various types of penetrations, ranging from complete multi-component sealing systems to intumescent (heat expanding) sealants and pillows to fiberglass or mineral wool packing. Select a firestop approach for your food, dairy, beverage, or pharmaceutical penetrations that provides the appropriate level of fire protection and hygienic sealing to protect your sanitary environment.

Stainless steel escutcheon plates are not fire-rated and they don’t provide hygienic seals around penetrants, so they are not the right choice for a fire-rated penetration application in sanitary environments.

Flexible silicone boots do not carry a fire rating themselves, but they properly seal penetrations that have been filled with one or more firestop insulating products. The fire-rated material inside the penetration gap is effectively sealed off from any exposure to your sanitary environment with a high-grade hygienic silicone seal that is temperature rated up to 500°F.

Product selection guide | |||||

|  |  |  |  |  |

Next Steps

As a hygienic processor, you work to ensure your plant environment is kept safe, secure, and clean, and the problem of maintaining high standards with piping thatpenetrates through floors and ceilings needs an effective solution.

That’s where Pipetite® comes in.

Pipetite is designed to completely seal around pipe and tube as it passes through walls and floors. Unlike metal wall plates or escutcheons, Pipetite is flexible, so it stays in place and maintains a seal despite pipeline vibration and movement.

Pipetite products are constructed of hygienic silicone material in compliance with Food and Drug Administration (FDA) specifications. Silicone rubber is resistant to cracking, weathering, extreme temperatures, and water. Even after testing equivalent to 158 years of outdoor use, Pipetite remains waterproof and shows no sign of degradation. Contributing to Pipetite's durability is a temperature rating of -40° to 500°F. Pipetite retains its flexibility indefinitely, regardless of the conditions.

Central States Industrial (CSI) stocks Pipetite in two different warehouses around the US, allowing customers to be reached on-demand. Pipetite is also stocked in several styles and sizes to fit different applications. For a complete overview, visit csidesigns.com.

A Guide to Wall Penetration

This technical guide is a general education tool for mechanical and electrical contractors, process designers and engineers, production managers, and anyone else who has a stake in ensuring that their processing environment is clean and safe.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.