Cut the Hassle: Hastelloy C-22 vs. C-276

Material selection is a combination of property, price, and product availability. There are many materials talked about in the industry and very few produced in the product forms required for a project. We often get into the difficult decision of which is the right material of choice for our purpose.

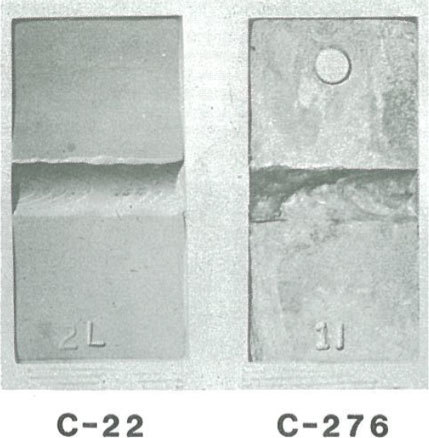

We frequently see that some of these alloys, such as Hastelloy® C-22® and Hastelloy® C-276®, get mixed up and/or welded together regularly.

Hastelloy is a representation of a family of corrosion-resistant alloys. Both C-22 and C-276 are from the Hastelloy family, and that similarity can lead to confusion, but C-22 has better overall corrosion resistance compared to C-276 and is often referred as the upgrade from C-276.

A higher percentage of chromium in C-22 provides better corrosion resistance in oxidizing environments, improving the life of the material significantly. Common severe oxidizing mediums include sodium chloride (NaCl), hydrochloric acid (HCl), and sulphuric acid (H2SO4). C-22 also shows outstanding resistance to ferric and cupric chlorides, acetic anhydride, formic and acetic acids, hot contaminated organic and inorganic acids, brine solutions, and seawater.

Hastelloy family

| Alloy | UNS Number | Chromium | Nickel | Molybdenum |

|---|---|---|---|---|

| Hastelloy C-22® | N06022 | 22% | 56% | 13% |

| Hastelloy C-276 | N10276 | 16% | 57% | 16% |

Hastelloy C-22 has been found to have outstanding resistance to pitting, crevice, and stress corrosion cracking when compared to Hastelloy C-276.

Both C-22 and C-276 have been tested in the oxidizing mediums for pitting and crevice corrosion. It has been proven that C-22 is more resistant to the oxidizing media, even at higher temperatures. However, C-22 and C-276 behave the same in reducing environments. Reducing agents include oxalic acids (C2H2O4), formic acids (HCOOH), and phosphorous acid (H2PO4).

Critical Pitting and Critical Crevice Corrosion Temperatures

| Alloy | CPT* (°C) | CPT* (°F) | CCCT** (°C) | CCCT** (°F) |

|---|---|---|---|---|

| Hastelloy C-22® | > 150 | > 302 | 102 | 212 |

| Hastelloy C-276 | 150 | 302 | 80 | 176 |

C-22 AND C-276 Weldability

C-22 has been regularly used as weld filler/consumable insert material because it provides better weldability and over alloying ability, thus improving corrosion resistance. C-22 also provides excellent resistance to intergranular corrosion in the heat-affected zone of the weldments compared to C-276.

Reference: Haynes technical H-2032 0621r information

C-22 AND C-276 AVAILABILITY

Availability is the most important material property. C-22 is readily available in the required product forms for the industry, whether that form is pharmaceutical grade tubing and fittings or round bar, sheet, and plate for other fabrication purposes. It is important to have the material available in reasonable quantity and in required time.

Although C-276 is available in some product forms, it can be difficult to find sanitary/high purity grade tubing and fittings in C-276. We have seen that there are some valves in Hastelloy C (could be C-22 or C-276) welded to tubing and fittings in C-22. Product availability is a key for completion of many projects.

C-22 AND C-276 Price Comparison

The cost per pound for these alloys is the same depending on the product form. C-22 is 2% less dense, giving an edge to C-22 on the price per square foot.

Each of these factors supports Hastelloy C-22 as the choice for longer life, better performance, and better return on investment (ROI).

Expert Bio

Yogini Dhopade, Product Manager - Alloys

Yogini Dhopade has three degrees, speaks four languages, and has traveled to ten different countries across the world. She has an unmatchable passion for metals and spends her time at CSI managing everything related to corrosion-resistant alloys.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.