Guidelines for Choosing the Right Type of CIP System

Maintaining a hygienic process environment that ensures product quality and purity is important for any processor. That’s where a good Clean-in-place (CIP) System comes in.

CIP is a method of cleaning sanitary process lines, vessels, and equipment that doesn’t require the equipment be removed or disassembled.

CIP Systems pump cleaning, rinsing, and sanitizing solutions through the same piping path as the product to eliminate product soil from all internal surfaces.

Advantages of a CIP System

- Minimizes Mistakes: Automating cleaning reduces the chance of human error that can contribute to an unsafe product.

- Keeps Employees Safe: Reduces chemical exposure by containing cleaning solutions within the system.

- More Production Time: As less production time is lost to cleaning, more time is spent making product.

- Product Quality: Reliable and repeatable cleaning means sustainable product quality and consistency. Less contamination means fewer product recalls and higher brand confidence.

- Utility Savings: Water and energy usage is reduced through repeatable cycle control.

Choosing the Right Type of CIP System

CIP systems vary widely in

- Configuration

- Capacity

- Quality

- Level of automation

These systems also vary by industry. Differences in product characteristics and regulatory considerations between the various processing industries impact the design of your CIP system.

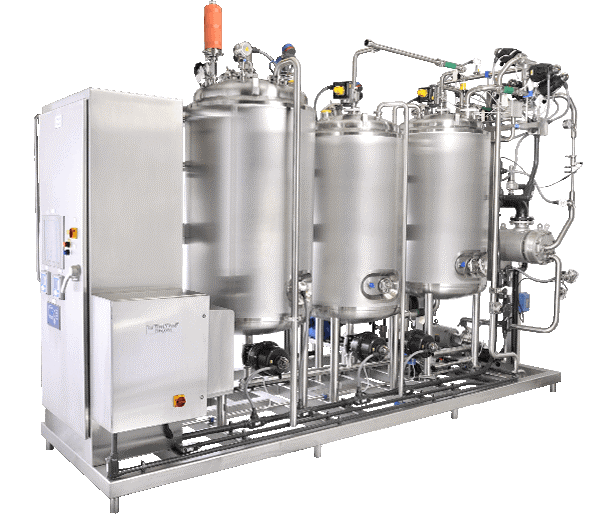

Depending on the system and the product being cleaned, your CIP system could be as simple as a self-contained skid to clean one small circuit or as complex as a large sophisticated system equipped to service multiple circuits or kitchens simultaneously.

There are some great questions to ask yourself before you build a CIP System, but to make sure you receive the maximum return on your CIP investment, processors are encouraged to partner with an experienced company that, above all, understands process systems and has a proven history of engineering effective custom CIP systems.

Needs analysis and proper planning ensure CIP System designs that improve processing, safety, and efficiency. When choosing the right type of CIP system, consider

- Your System Layout

- Your Budget

Know Your System Layout

Designing a custom CIP system for your specific needs starts with deciding whether your system should be centralized or distributed.

Centralized vs Distributed

A centralized CIP system is a single system that delivers cleaning solutions to an entire process facility. It can supply many different circuits and coordinate a large number of operations from a single location so operators can manage processes using a central set of controls.

The location of a centralized CIP system in a plant is important. If all processing areas are relatively close in proximity and they all have similar cleaning requirements, a centralized system can be cost effective.

Centralized systems tend to be larger in size and scope than distributed systems.

A distributed CIP system uses local dedicated systems to service individual sections of the plant.

A distributed CIP system uses local dedicated systems to service individual sections of the plant.

This strategy works well for

- Manufacturers that have process areas in remote locations that are difficult or costly to reach with piping from a centralized CIP unit.

- Operations with very specific cleaning requirements that are incompatible with cleaning requirements of other operations, such as stringent cross-contamination demands.

- Manufacturers who are new to clean-in-place operations.

- Manufacturers that want to clean-in-place but are limited by budget constraints.

Transportable CIP skid systems can be especially useful in a distributed CIP system. All of the equipment needed to clean-in-place is mounted on a compact, self-contained skid that can be easily transported to any location in the plant.

The mobility of these systems gives users considerable flexibility in their cleaning operations. They are an excellent solution for processors who are budget conscious or cleaning in place for the first time.

The Compact CIP from CSI is a mobile unit that also serves as a fully functional, automated CIP system. The seven-inch touchscreen Human Machine Interface (HMI) displays the control interface. From this screen temperature, concentration, flow, and cycle time setpoints can be configured.

A variety of CIP washes can be selected after the parameters are established. With a touch of a button, the system runs the selected wash automatically, until each parameter is met and the wash is complete. These washes can be monitored, alarms can be viewed, and cycle trends displayed all from the HMI.

Know Your Budget

The full scope of CIP features and capabilities is largely based on processor needs and budget.. Knowing your application and budget goes a long way in determining whether you need a basic or complex system.

Basic vs Complex

At its most basic, cleaning in place can be a manual one-tank, single-use system that sends solution through a single circuit and then sends it to drain. This strategy isn’t very environmentally friendly and is relatively expensive in terms of chemicals, water usage and effluent costs, but it can be a valid strategy for small systems and for avoiding cross-contamination.

Single-use systems can also be well suited to cleaning heavy soil loads that make solution recovery and re-use impractical. A single-tank system carries a smaller initial price tag than a multi-tank system but cleaning can be much slower since operators must wait for the tank to fill and drain for each step.

At the other end of the spectrum, a CIP system can be as complex as a fully automated multi-tank, multi-circuit apparatus that recovers and re-uses solutions while cleaning in parallel with processing activities. All of the cleaning and rinsing solutions can be pre-charged into their own tank and pre-heated to their optimum preset temperature, ready to go.

The initial investment for complex systems can be higher, but they are designed to be ultra-cost-effective by

- Reducing downtime

- Reclaiming and reusing solutions

- Closely monitoring water, chemical, and energy usage

Highly automated systems that systematically conserve resources can provide a higher overall return on investment than simpler manual systems.

ROI on CIP Investment

The more sophisticated a CIP system is (the more tanks, the more advanced the controls), the greater the initial investment to purchase and install a system.

CIP is an investment that provides consistent long-term returns. Every time you run a cleaning cycle, you are getting back valuable production time previously lost to slow, inefficient cleaning practices.

Saving just a few minutes of cleaning time each week can generate thousands of dollars in additional production. Depending on cleaning frequency and product value, many processors commonly see a full payback on their CIP system in 1-2 years by saving cleaning time each week.

Next Steps

Purchasing and installing a CIP system for your processing facility is a considerable undertaking, requiring analysis, planning and above all, partners.

The best first steps are

- Create a team of knowledgeable operators

- Create a team of managers from multiple departments

- Connect with a trusted company that has vast experience in designing and building process and CIP systems

That’s where we come in.

CSI can engineer, design, and fabricate a custom Clean-in-place System to meet your exact hygienic processing needs. CIP equipment from CSI helps you control, monitor, and document the cleaning methods that are essential to sanitary processing.

With CSI's state-of-the-art, climate-controlled fabrication shop, the quality of equipment leaving our facility is second to none. We offer in-house, Level II inspection in accordance with the latest ASNT recommended Practice No. SNT-TC-1A, so you can be certain your equipment meets industry standards.

To speak with a CIP expert request a quote below or call 800.654.5635.

Clean-in-place Buying Guide

This Buying Guide for Clean-in-Place Solutions is a comprehensive resource for anyone who designs, owns, or operates processing systems and wants information about all aspects of CIP Systems.

ABOUT CSI

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.